ACCESSORIES FOR AIR BLASTER SYSTEM

AIRCHOC® AIR BLASTER

17 November 2022MACSYS Multi mechanism air cannon

18 November 2022

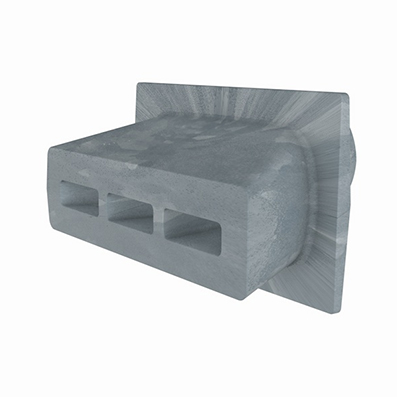

NOZZLES FOR AIRCHOC® AIR BLASTERS

Nozzles direct the air flows towards sensitive clogging zones. They are mainly installed in cement plants at the heart of the Process (cooler, cyclone, smoke chamber, ducts,).

Whether in high or low temperature version, nozzles are installed to operate a cleaning in the preheating towers.

Depending on how the nozzle is installed, the air of the air cannon will have a precise directional impact to reach difficult areas.

Steel or refractory stainless steel version.

For all of its range of nozzles, Standard Industrie provides the following diameters: DN100 & DN150.

- Efficient cooling

- Flexible usage for complete kilns>

- Easy installation

- Targeted cooling on kiln’s circumference

- Visits & technical recommendations (dimensioning & positioning)

- Supply of the installation drawin

- We offer complete installation of our equipment if needed>

- Material: Refractory Stainless steel

- Available fluid: Compressed air or inert gas

- Temperature: 750 to 1200°C

- Type of manufacture: Moulded or dished according to

- Application area: Recommended for high temperature, applications can be immersed in a refractory concrete

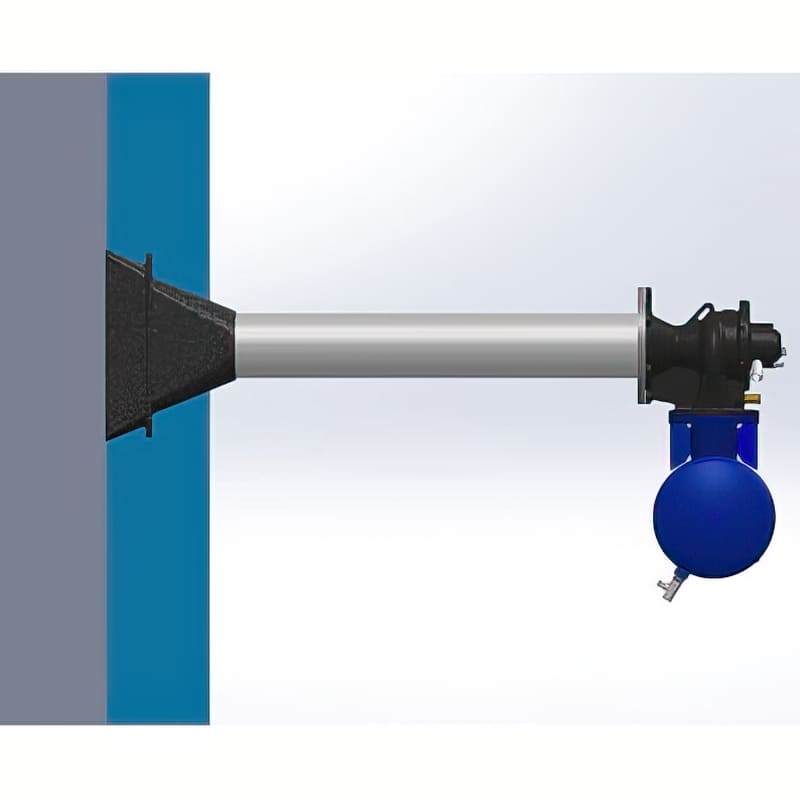

ISOLATOR FOR AIRCHOC® AIR CANNON

The AIRCHOC® isolation system allows a barrel to be isolated for safe maintenance.

It protects the AIRCHOC® during special operations in the silo (explosive, overpressure) and thus prevents an accumulation of product in the head or in the tank. These accumulations of dust are sources of failure or reduced performance of the AIRCHOC®.

The system can be installed on a nozzle already in place between the nozzle flange and the AIRCHOC® flange.

A padlock is included (lockout possible) to isolate the entry from the tapping. The AIRCHOC® can then be safely dismantled from the isolator without the latter becoming detached from the connection.

diameters: DN100 & DN150.

ADVANTAGES

• Protects the AIRCHOC® and maintenance operators

• Remains attached to the connection if the AIRCHOC® is dismantled

• Effortless use thanks to the large play and the low mass of the moving part

• Low thickness to maintain the performance of AIRCHOC®

• Installation possible vertically or horizontally

• Easy maintenance of the isolator: possibility of removing the guillotine in case of jamming or clogging by the two plates at the ends.