Eliminate blockages and builds-up in storage units and gas lines present in the process. Reduce material flow problems before and after combustion

Our services enable blockages of sand, lime, cement, ash, raw meal, clinker

Here are some examples of our cleaning solutions :

- Cleaning during furnace/Kiln inlet shutdowns

- Cleaning the feed hopper chute

- Cleaning of furnace inlets and bypass, tertiary duct

- Cleaning of the lime kiln – vault

- Cleaning of the gas ducts

- Cleaning of the smoke box

- Cleaning of the preheating tower

- Cleaning of cyclone and gooseneck

- Cleaning of the crusher

- Cleaning of dust collector filter, catalyst, SCR

- Cleaning of the slide

- Cleaning of the flour chute

- Cleaning of and storage silos, cement silos, raw meal silos

- Cleaning of bridging

=> Cleaning solution with AIRCHOC air cannon cleaning system, air blaster, Explosion proof air blaster.

Reduce dust and recover material at various locations in the plant for each step of cement production :

We offer solutions for vacuuming of cement, clinker, lime, ash, coal, iron ore, clay, alternative fuels

Some examples of our industrial vacuum solutions :

- Cleaning of raw material storage area

- Cleaning of the grinding area

- Cleaning of packaging and bagging area

- Cleaning of cement mills

- Cleaning of kiln bridging

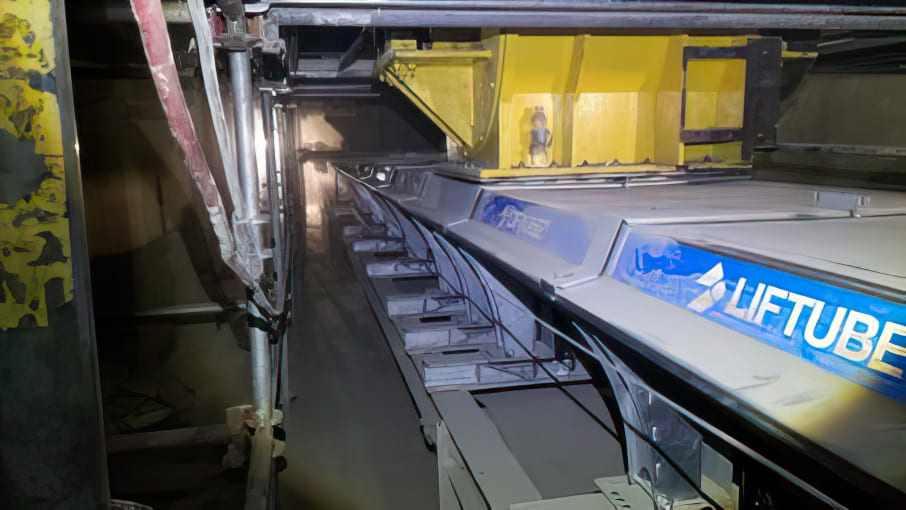

Eliminate overflow from the conveyor belt, transport belt

Standard Industrie offers solutions to eliminate overflow from the conveyor belt and transport belt.

- Containment of the conveyor, sealing of the belt

- Dust suppression, sealing

- High temperature applications for clinker transportation post cooler,

- Dust reduction in Mill Buildings/Tunnels/Coal conveyors,

- Containment of low density alternative fuels on incline conveyors.

=> Conveyor containment and belt sealing solution: Thanks to the belt containment provided by the LIFTUBE® device, the product circulates as if it were in a hermetic envelope, which reduces the flow of material to the outside and the loss of material from the belt.