Cleaning solution for for the food industry

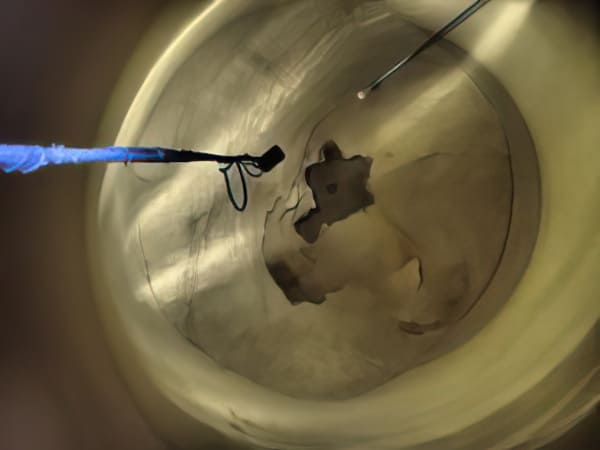

Our air gun cleaning solutions to fluidize the production of animal or human food remove material deposits, clogging and concretions in storage units and material conveyance chutes. Depending on the moisture content of the silo, clogging of sugar, soya, bran and flour can occur.

Here are some examples of our industrial cleaning solutions :

- Cleaning of raw material storage hopper

- Cleaning of grain silo, soybean silo, bran silo

- Preventing the bran from getting clogged by placing air cannons on the storage unit

- Elimination of material blockage at the unloader extraction

- Cleaning of feed storage hoppers

- Cleaning with ATEX 21 standard equipment, especially to facilitate the flow of crystal sugar

In the food industry, the recovery systems under the silos are generally Archimedean screws, vibrating tubes, pneumatic transport. The use of air cannons will allow a regular feeding of the recovery equipments, which are often regulation and dosage elements.

Suction solution for the food industry

Food production is subject to sanitary requirements and the ATEX standard, which network vacuum machines can meet.

Some examples of our industrial dust extraction solutions :

- Cleaning by centralized vacuum system of storage areas

- Industrial vacuuming of the packaging area

- Suction of fine grains or granules

- Cleaning by vacuum of dust from the food production process

Sealing of conveyor belts for the food industry

Standard Industrie offers solutions to eliminate overflow from the conveyor belt and transport belt.

The LIFTUBE® belt design provides a tight envelope for the product to flow through, thus reducing the risk of material escaping from the belt and the loss of material from the belt. Because the cover is clip-on, it snaps perfectly into the upper grooves of the edge supports and therefore provides a perfect seal to the system. This seal is also achieved through the foam-laminated hoops that enclose the strip at each end.

It is these advantages that can create a sanitary interest when the transported product must be protected from the outside environment.