AN UNUSUAL IDEA: THE PRINCIPLE OF THE FLUSH

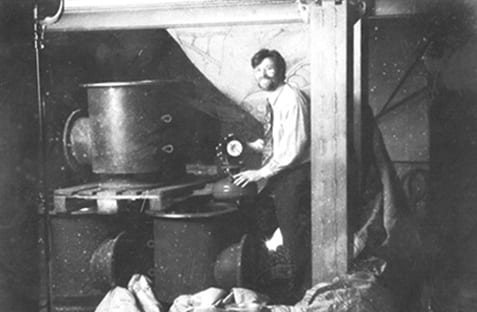

In 1977, Hervé Simoëns was regularly confronted with the constraints of getting rid of waste in silo or hopper type storage units. At the time, to solve this problem, the inflatable panel was the main solution. Certainly efficient, this principle didn’t however apply to all kinds of materials. Moreover, it led to significant costs in terms of installation and upkeep as well as maintenance difficulties.

The origin of the AIRCHOC® air canon is based on the principle of the flush. The idea was to develop a mechanism located outside of its area of intervention. However, the energy had to be different. In the industry, compressed air is the least harmful energy and is available everywhere, or almost everywhere.

For several months, research and tests were carried out based on this principle by imagining an instantaneous opening system. The concept seemed promising.

Through sheer perseverance, Hervé Simoëns took out his first patent on the AIRCHOC® air canon in 1978 and created STANDARD INDUSTRIE International.

The company base is in the North of France, it started with a market research approach in this region. The first customers to place their trust in it were:

Very quickly, these recommendations attracted other customers from similar groups and industries.

In 1981, STANDARD INDUSTRIE International was crossing borders. Up until then it was only managing requests from France. It then put its know-how to use with LAFARGE Cements in MEKNES (Morocco)

Strengthened by his budding expertise and knowledge of the market, H. Simoëns therefore decided to set up branches in Europe: Spain, Italy, Belgium, the UK and Germany. From the 90s, its development spread to Mexico, South Africa, Canada, the USA, China and South East Asia. In 2012, the American branch STANAM INDUSTRIES opened in Clearwater, FL.

In addition to its geographical development, STANAM INDUSTRIES diversified its range of solutions:

Since 1978, STANDARD INDUSTRIE International has therefore been specialising and diversifying in the design and manufacturing of equipment. Its aim: to facilitate the conveying of bulk material and powder products safely while respecting the environment.