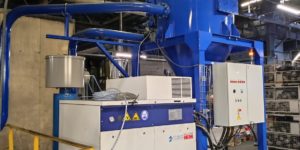

INC, industrial vacuum cleaner

MAINTENANCE – SAV

12 December 2022INDUSTRIAL VACUUM CLEANING GAD

21 November 2022

INSTALLATION OF CENTRALISED CLEANING

- Application: Cleaning & pumping

- Motor: Electrical

- Collection: Silo

- Operators : Up to 6

- Performance (product density 1): Up to 27.5 short ton/hour

- Air output: Up to 2,354 CFM

- Vacuum pressure: Up to 23” HG

- Collection capacity: Up to 1,135 gal

- Particle size: Up to 2”

- SAVINGS: Immediately operational

- QUICK & SIMPLE to deploy

- RECYCLING: Many possibilities for emptying: big bag/barrel/skip/continuous handling

- SAFE: Solid and simple technology to help you operate in heavy industrial environments with the highest level of safety and productivity

- Visits & recommendations

- On-site test/demonstration

- 1-year-warranty

- 2 after-sales-service visits included in the warranty/li>

- Rental & leasing

- Extension of warranty

- Inspection contract

- Maintenance contrac

- Statement, network study, implementation

- On-site & external training (STANDARD INDUSTRIE training institute: IFSI – No. 31 59 05660 59)

OPTIONS:

- Anti-explosion system: vents or flame protection

- Different types of valves depending on the method of emptying

- Remote control

ACCESSORIES:

- Flexible hoses: DN 100 to 50, rubber/polyurethane/PVC

- Sensors: DN 100 to 50, steel/stainless steel/aluminium/PVC

- Suction port, lances etc.

Case studies INC

- All

- Glass industry

- Lime

- Sand