AIRCHOC® MAINTENANCE PROGRAM

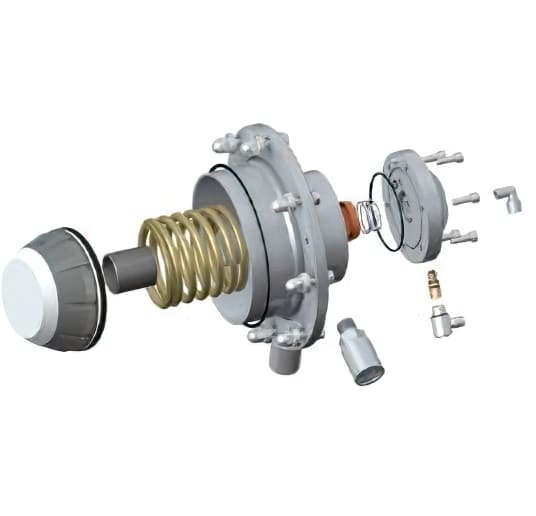

MACSYS Multi mechanism air cannon

18 November 2022Message envoyé

21 November 2022

The most cost effective solution and a preserved environment

=> To eliminate the risk of production stoppage or excessive waiting time for the operators, STANDARD INDUSTRIE has developed a maintenance system :

- A case containing a complete Airchoc® mechanism is kept in stock by the Airchoc® air blaster user.

- As soon as maintenance is required, the used mechanism is simply replaced by the mechanism contained in the case.

- The used mechanism is then simply replaced into the case and shipped to Standard Industrie to be cleaned and repaired by our specialized technicians

- maintenance.

- INTERVENTION SPEED: No need to wait for a technician. This means no more slowing down production due to a malfunction of the air cannons.

- PROFITABILITY

- EASY: 10 minutes to replace the blocked mechanism

- Visits & technical recommendations (dimensioning & positioning)

- Supply of the installation drawing

- We offer complete installation of our equipment if needed

- Up to 3-year warranty

- In-house & external training

- After-sales service & maintenance contract

- Standards compliance

Case studies